Вернуться

Chemicals for the Yankee cylinder

Paper creping is a necessary process in the production of sanitary and hygienic types of papers.

To ensure the effectiveness of the paper creping process, it is necessary to ensure the adhesion of the paper web on the surface of the drying cylinder. The use of the Petrofer coating, which is fed to the surface of the yankee cylinder using a dosing unit of our own design, allows us to increase the productivity of the machine, achieving higher quality and softness of paper, protect the surface of the cylinder and increase the service life of the crepe scrapers. Product trademarks: COTAC H, COTAC P, COTAC C, RELEASE AGENT.

Petrofer system

Petrofer offers a system consisting of dosing equipment and a set of chemicals that allow you to accurately control and manage the parameters of sanitary and hygienic paper.

COTAC H is a base coating (coating) that protects the surface of the yankee cylinder, giving adhesion. A large number of modifications allows you to choose the optimal product for any BDM.

RELEASE AGENT - release, a product for improving the removal of paper cloth. Usually based on mineral or vegetable oil.

COTAC C is a phosphate containing a modifier. Protects the surface of the yankee cylinder, prevents corrosion. It is recommended to be constantly used as a third component of couting, especially on metallized cylinders.

COTAC 460P/480 P is a product specially designed for processing the edges of the Yankee cylinder, prevents the formation of carbon deposits, cleans deposits and protects the surface of the edge of the Yankee cylinder. It has proven itself very well especially on high-speed BDM

To ensure the effectiveness of the paper creping process, it is necessary to ensure the adhesion of the paper web on the surface of the drying cylinder. The use of the Petrofer coating, which is fed to the surface of the yankee cylinder using a dosing unit of our own design, allows us to increase the productivity of the machine, achieving higher quality and softness of paper, protect the surface of the cylinder and increase the service life of the crepe scrapers. Product trademarks: COTAC H, COTAC P, COTAC C, RELEASE AGENT.

Petrofer system

Petrofer offers a system consisting of dosing equipment and a set of chemicals that allow you to accurately control and manage the parameters of sanitary and hygienic paper.

COTAC H is a base coating (coating) that protects the surface of the yankee cylinder, giving adhesion. A large number of modifications allows you to choose the optimal product for any BDM.

RELEASE AGENT - release, a product for improving the removal of paper cloth. Usually based on mineral or vegetable oil.

COTAC C is a phosphate containing a modifier. Protects the surface of the yankee cylinder, prevents corrosion. It is recommended to be constantly used as a third component of couting, especially on metallized cylinders.

COTAC 460P/480 P is a product specially designed for processing the edges of the Yankee cylinder, prevents the formation of carbon deposits, cleans deposits and protects the surface of the edge of the Yankee cylinder. It has proven itself very well especially on high-speed BDM

Dyes for paper and cardboard, fixers

For coloring paper and cardboard in bulk, we offer the following types of dyes:

Direct anionic and basic cationic dyes are used for dyeing bleached cellulose fiber. They have proven themselves well for coloring sanitary and hygienic types of papers in both intense colors and pastel. A wide range of colors allows you to solve the problem of coloring paper in bulk in almost all cases.

Fixing agents - for reliable fixation of direct anionic dyes, we recommend using fixators. Due to the cationic charge, they improve the retention of dye, fiber and fillers, thanks to this it is possible to increase the resistance to washing in finished products, which is especially important in the production of sanitary types of papers, especially saturated colors.

Direct anionic and basic cationic dyes are used for dyeing bleached cellulose fiber. They have proven themselves well for coloring sanitary and hygienic types of papers in both intense colors and pastel. A wide range of colors allows you to solve the problem of coloring paper in bulk in almost all cases.

Fixing agents - for reliable fixation of direct anionic dyes, we recommend using fixators. Due to the cationic charge, they improve the retention of dye, fiber and fillers, thanks to this it is possible to increase the resistance to washing in finished products, which is especially important in the production of sanitary types of papers, especially saturated colors.

Moisture-resistant resin

145C WSA is a highly concentrated cationic polyamide epichlorohydrin resin and is used to impart moisture-resistant properties to paper.

Functional features:

145C WSA quickly attaches to the fiber due to the cationic charge. During the drying process of the paper web, this chemical is embedded in the structure of the cellulose fiber and its subsequent maturation.

145C WSA allows you to achieve higher performance:

- dry strength;

- breaking length;

- pushing;

- abrasion resistance.

145C WSA promotes retention of fillers and pigments.

Functional features:

145C WSA quickly attaches to the fiber due to the cationic charge. During the drying process of the paper web, this chemical is embedded in the structure of the cellulose fiber and its subsequent maturation.

145C WSA allows you to achieve higher performance:

- dry strength;

- breaking length;

- pushing;

- abrasion resistance.

145C WSA promotes retention of fillers and pigments.

Products for the dissolution of moisture-resistant marriage

DeCotac it is a strong oxidizing agent used to

dissolve moisture-resistant papers and cardboard during the processing of scrap. Quickly and effectively destroys moisture-resistant components at neutral pH values.

The oxidative effect is more pronounced at elevated temperatures.

Repulpase is a drug based on enzyme technologies for the dissolution of moisture–resistant marriage at neutral pH values. Safe to use and store. More information here.

dissolve moisture-resistant papers and cardboard during the processing of scrap. Quickly and effectively destroys moisture-resistant components at neutral pH values.

The oxidative effect is more pronounced at elevated temperatures.

Repulpase is a drug based on enzyme technologies for the dissolution of moisture–resistant marriage at neutral pH values. Safe to use and store. More information here.

Cleaning and detergents

To ensure trouble-free production for our customers, we offer a full range of chemicals for cleaning pipelines, nets and cloths.

The Feroclean product group includes both alkaline and acidic formulations, solvent-based cleaners with and without volatile organic compounds.

The StickStop product is designed for passivation of the BDM mesh, prevents the loss of "sticky" and other contaminants of the mesh.

All our cleansing formulations do not contain complexing agents.

Constant or shock washing with Feroclean compounds maintains a good dehydrating ability of cloths and nets, provides a uniform moisture profile and prolongs the service life. This in turn increases the efficiency and productivity of the paper machine.

The selection of Feroclean products is carried out by our technical specialists based on the analysis of existing problems on the BDM.

The Feroclean product group includes both alkaline and acidic formulations, solvent-based cleaners with and without volatile organic compounds.

The StickStop product is designed for passivation of the BDM mesh, prevents the loss of "sticky" and other contaminants of the mesh.

All our cleansing formulations do not contain complexing agents.

Constant or shock washing with Feroclean compounds maintains a good dehydrating ability of cloths and nets, provides a uniform moisture profile and prolongs the service life. This in turn increases the efficiency and productivity of the paper machine.

The selection of Feroclean products is carried out by our technical specialists based on the analysis of existing problems on the BDM.

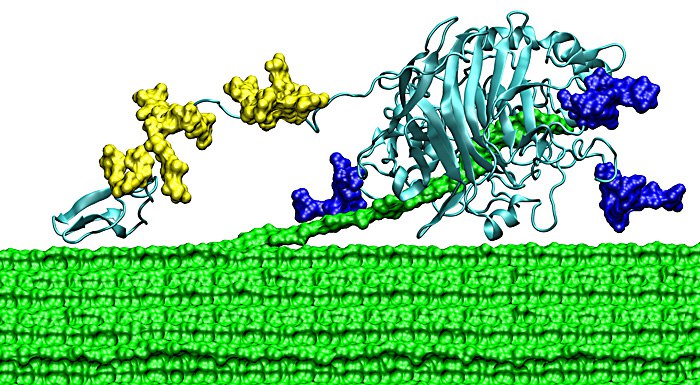

Enzymes and chemicals for deinking

Preparations for enzyme modification of fibers

Enzymes for fiber modification are used both in the production of paper from primary fiber and on waste paper raw materials. These products can improve the water output of paper pulp, increase retention and increase the physical and mechanical properties of the finished paper.

More information about deinking chemicals can be found on the Enwatec website.

Enzymes for fiber modification are used both in the production of paper from primary fiber and on waste paper raw materials. These products can improve the water output of paper pulp, increase retention and increase the physical and mechanical properties of the finished paper.

More information about deinking chemicals can be found on the Enwatec website.

Coatings for imparting barrier properties

The company Schill + Seilacher GmbH produces a wide range of innovative eco-friendly materials for various barrier coatings required in the production of packaging cardboard, sub-parchment and other special types of papers, the production of paper disposable tableware and other applications.

These products do not contain fluorinated compounds and are therefore ideal for applications where there is direct contact with a person.

A brief overview of the proposed materials:

Ukaphob series – hydrophobic and oleophobic coatings

Ukaphob 5200 series – anti-slip coatings, high-friction coatings

Ukaprint series – barrier coatings for flexographic printing

Ukadur series – barrier coatings for mechanical protection and thermal insulation

Ukacross/Ukasol series – materials for accelerating the crosslinking of the coating polymer and improving the connection of paper with problematic coatings

Despumol series – special defoamers

Ukadur X series – products for making paper fire-resistant

In addition to these solutions, Schill + Seilacher offers materials for special antibacterial coatings, electrically conductive coatings and other applications.

For more information, please contact our specialists.

These products do not contain fluorinated compounds and are therefore ideal for applications where there is direct contact with a person.

A brief overview of the proposed materials:

Ukaphob series – hydrophobic and oleophobic coatings

Ukaphob 5200 series – anti-slip coatings, high-friction coatings

Ukaprint series – barrier coatings for flexographic printing

Ukadur series – barrier coatings for mechanical protection and thermal insulation

Ukacross/Ukasol series – materials for accelerating the crosslinking of the coating polymer and improving the connection of paper with problematic coatings

Despumol series – special defoamers

Ukadur X series – products for making paper fire-resistant

In addition to these solutions, Schill + Seilacher offers materials for special antibacterial coatings, electrically conductive coatings and other applications.

For more information, please contact our specialists.