Вернуться

Activated carbon Filter media

The offered activated carbon filter materials are manufactured by our partner - HelsaTech GmbH in Germany.

This type of filter material consists of two layers of nonwoven fabric with an adsorbent located between them. Depending on the application, these materials can be produced with different activated carbon content - from 160 g/m2 to 475 g/m2.

Thanks to the selection of high-quality raw materials, these materials have excellent adsorption properties, good corrugability and are widely used both in industrial and household air purification, and in the automotive industry in the production of cabin filters.

When using special activated carbons, we can offer filter materials for special tasks, for example, the removal of hydrogen sulfide.

This type of filter material consists of two layers of nonwoven fabric with an adsorbent located between them. Depending on the application, these materials can be produced with different activated carbon content - from 160 g/m2 to 475 g/m2.

Thanks to the selection of high-quality raw materials, these materials have excellent adsorption properties, good corrugability and are widely used both in industrial and household air purification, and in the automotive industry in the production of cabin filters.

When using special activated carbons, we can offer filter materials for special tasks, for example, the removal of hydrogen sulfide.

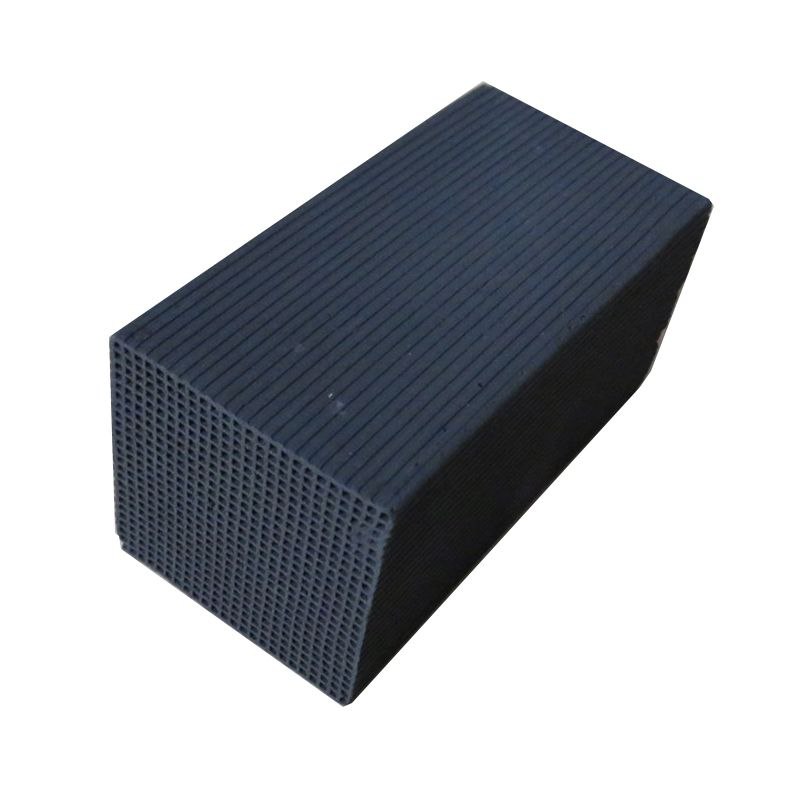

Coal Honeycombs

Helsa Sorbexx CS carbon honeycombs are produced by extruding a homogeneous mixture of powdered activated carbon and ceramic binder. At the same time, activated carbon is a functional material, and a ceramic binder provides a supporting structure. The ratio between activated carbon and binder determines the adsorption capacity of the material. Especially finely ground activated carbon particles are so integrated into the ceramic structure that they are completely accessible to molecular contaminants and form the maximum reaction surface area. The surface area can vary due to the different cross-section of the honeycomb and thus determines the kinetics of adsorption.

Special properties

- high adsorption efficiency due to the use of powdered activated carbon

- high mechanical strength and easy handling

- no dust for easy and reliable operation

Construction and design

- low flow resistance reduces energy costs

- high reaction surface area guarantees long-term efficiency

- possible different activated carbon content and correspondingly high capacity

- a modular system of different blocks and different shapes of honeycombs allow you to provide simple and customized solutions

Physical and chemical properties

- temperature stability and thermal regenerability

- resistance to fire and chemical attack, therefore it is also used for ozone destruction

- stability to water, therefore it is also used in the liquid phase

- suitable as a carrier for catalysts, impregnation and functionalization

Application areas

- industrial cleaning of outgoing, draw-in and ventilation air

- application in the clean room technique

- blowing of buildings (HVAC)

- vehicles

- home, kitchen and sanitary appliances

- respiratory protection

- purification of drinking water, industrial and waste water

- cleaning of tobacco smoke

Special properties

- high adsorption efficiency due to the use of powdered activated carbon

- high mechanical strength and easy handling

- no dust for easy and reliable operation

Construction and design

- low flow resistance reduces energy costs

- high reaction surface area guarantees long-term efficiency

- possible different activated carbon content and correspondingly high capacity

- a modular system of different blocks and different shapes of honeycombs allow you to provide simple and customized solutions

Physical and chemical properties

- temperature stability and thermal regenerability

- resistance to fire and chemical attack, therefore it is also used for ozone destruction

- stability to water, therefore it is also used in the liquid phase

- suitable as a carrier for catalysts, impregnation and functionalization

Application areas

- industrial cleaning of outgoing, draw-in and ventilation air

- application in the clean room technique

- blowing of buildings (HVAC)

- vehicles

- home, kitchen and sanitary appliances

- respiratory protection

- purification of drinking water, industrial and waste water

- cleaning of tobacco smoke