Вернуться

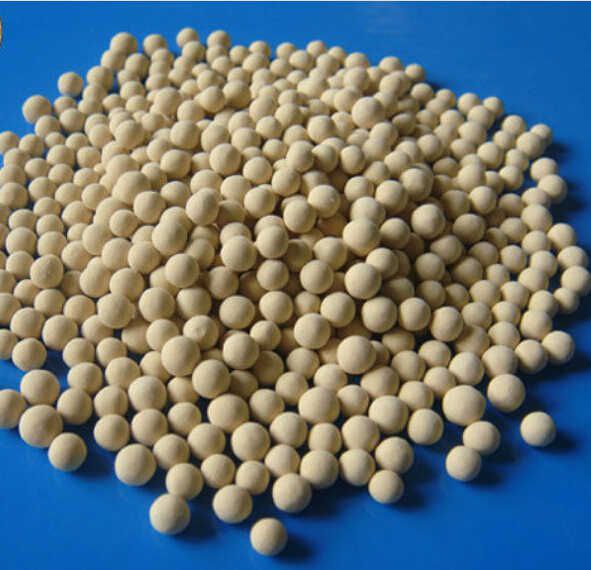

Carbon Molecular Sieves

Shirasagi CarboTech Carbon Molecular Sieves

As the exclusive distributor of CarboTech AC GmbH, we offer Shirasagi and CarboTech carbon molecular sieves for various applications.

CarboTech AC GmbH is the inventor of carbon molecular sieves and remains to this day one of the leading manufacturers of UMS in the world for enterprises operating on the technology of short-cycle pressure adsorption (CCA). A wide range of high-quality UMS offered by CarboTech AC GmbH finds application in many areas where CCA technology is used. Having focused on products based on coconut coal, CarboTech AC GmbH offers materials with an excellent price/quality ratio for nitrogen generators, biogas quality improvement and hydrogen purification, which occur using CCA technology.

Working with carbon molecular sieves from CarboTech AC GmbH, the client receives the following advantages:

excellent working properties of the product

excellent product quality

impressive mechanical properties (high hardness, low dust formation, no fine fraction)

comprehensive technical support

The high quality of carbon molecular sieves from CarboTech AC GmbH is confirmed by a large number of customers all over the world and is based on the experience and knowledge accumulated over 40 years.

Shirasagi MSC CT-350 is a universal carbon molecular sieve for nitrogen generators, which has proven itself well at many enterprises of the Russian Federation and CIS countries.

Packaging – barrels of 137 kg (200 liters), constantly in stock.

CarboTech CMS H2 is used to purify hydrogen from various gases using CCA technology at the outlet of a steam converter, a catalytic converter and ethylene plants.

Other carbon molecular sieves by Shirasagi and CarboTech can also be offered on request.

Basic principles of CCA technology on the example of a nitrogen generator:

The CCA process used to generate nitrogen can be divided into two phases. In the initial phase, carbon molecular sieves adsorb oxygen from compressed air, which contains 79% nitrogen and 21% oxygen. During this phase, pure nitrogen in the form of gas can be obtained at the outlet. In the second phase, oxygen under low pressure exits the adsorber and after that the next cycle can begin.

The connection between the two adsorbers, which operate in different phases alternately, allows for continuous production of high purity nitrogen.

The CCA technology makes it possible to efficiently produce high-purity nitrogen on site for the protection of pipelines and tankers, for the production of plastics and fibers, for the storage of rapidly perishable products and beverages, for the heat treatment of metals and processes in the electronics industry.

You can get more detailed information about the products offered for this technology by sending a request to our company.

As the exclusive distributor of CarboTech AC GmbH, we offer Shirasagi and CarboTech carbon molecular sieves for various applications.

CarboTech AC GmbH is the inventor of carbon molecular sieves and remains to this day one of the leading manufacturers of UMS in the world for enterprises operating on the technology of short-cycle pressure adsorption (CCA). A wide range of high-quality UMS offered by CarboTech AC GmbH finds application in many areas where CCA technology is used. Having focused on products based on coconut coal, CarboTech AC GmbH offers materials with an excellent price/quality ratio for nitrogen generators, biogas quality improvement and hydrogen purification, which occur using CCA technology.

Working with carbon molecular sieves from CarboTech AC GmbH, the client receives the following advantages:

excellent working properties of the product

excellent product quality

impressive mechanical properties (high hardness, low dust formation, no fine fraction)

comprehensive technical support

The high quality of carbon molecular sieves from CarboTech AC GmbH is confirmed by a large number of customers all over the world and is based on the experience and knowledge accumulated over 40 years.

Shirasagi MSC CT-350 is a universal carbon molecular sieve for nitrogen generators, which has proven itself well at many enterprises of the Russian Federation and CIS countries.

Packaging – barrels of 137 kg (200 liters), constantly in stock.

CarboTech CMS H2 is used to purify hydrogen from various gases using CCA technology at the outlet of a steam converter, a catalytic converter and ethylene plants.

Other carbon molecular sieves by Shirasagi and CarboTech can also be offered on request.

Basic principles of CCA technology on the example of a nitrogen generator:

The CCA process used to generate nitrogen can be divided into two phases. In the initial phase, carbon molecular sieves adsorb oxygen from compressed air, which contains 79% nitrogen and 21% oxygen. During this phase, pure nitrogen in the form of gas can be obtained at the outlet. In the second phase, oxygen under low pressure exits the adsorber and after that the next cycle can begin.

The connection between the two adsorbers, which operate in different phases alternately, allows for continuous production of high purity nitrogen.

The CCA technology makes it possible to efficiently produce high-purity nitrogen on site for the protection of pipelines and tankers, for the production of plastics and fibers, for the storage of rapidly perishable products and beverages, for the heat treatment of metals and processes in the electronics industry.

You can get more detailed information about the products offered for this technology by sending a request to our company.

Activated carbons

Our company offers the following activated carbons both from CarboTech AC GmbH and from leading manufacturers from Asia.

These adsorbents are produced both on a coconut and coal-based basis with a certain granulometric composition and sorption capacity, depending on the application and the tasks set.

For more information, please contact the specialists of our company.

Crushed activated carbons

Main application areas:

- preparation of drinking water

- wastewater treatment

- condensate purification at oil refining enterprises

- production of cigarette filters

Granular activated carbons

Main application areas

- recovery of solvent vapors

- air and gas purification

- wastewater treatment

Powdered activated carbons

Main application areas

- wastewater treatment

- pharmaceutical industry

Impregnated activated carbons

Main application areas:

- purification of biogas and landfill gas

- preparation of drinking water

Catalytic activated carbons

These adsorbents are produced both on a coconut and coal-based basis with a certain granulometric composition and sorption capacity, depending on the application and the tasks set.

For more information, please contact the specialists of our company.

Crushed activated carbons

Main application areas:

- preparation of drinking water

- wastewater treatment

- condensate purification at oil refining enterprises

- production of cigarette filters

Granular activated carbons

Main application areas

- recovery of solvent vapors

- air and gas purification

- wastewater treatment

Powdered activated carbons

Main application areas

- wastewater treatment

- pharmaceutical industry

Impregnated activated carbons

Main application areas:

- purification of biogas and landfill gas

- preparation of drinking water

Catalytic activated carbons

Zeolite Molecular Sieves

Our company offers zeolite molecular sieves Koestrolith company CWK.

Main application areas:

- oxygen generators operating on CCA and WCCA technology

- dehumidifiers of air and gases

- hydrogen purification plants using CCA technology

Main application areas:

- oxygen generators operating on CCA and WCCA technology

- dehumidifiers of air and gases

- hydrogen purification plants using CCA technology